Colored Concrete Flooring

Acrylic Based water soluble UV resistant Pigments are used for making our unique color concrete floors. The product is simply applied using a brush / roller / spray on any old / new concrete flooring surface. (with proper surface preparation / cleaning). A range of colors are available and this method replaces the use of EPOXY / PU and can be used for colored floorings in industrial, commercial, residential and infrastructure applications.

Features:

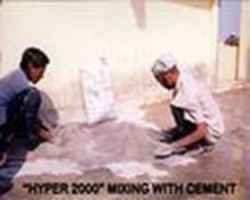

Concrete Flooring Admixture Hyper 2000

Rice Husk Ash is manufactured by Dr. R.N. Krishna Ph.D., (Civil Engineer) a specialist in the field of admixtures and concrete technology. Hyper 2000™ Rice Husk Ash contains a special blend of siliceous aggregates & abrasion resistant material and inert fillers and when added to cement greatly improves the durability properties of mortar or concrete. The resultant mix with Hyper 2000™ exhibits the following properties

Applications:

Used in:

Specifications:

| Specific gravity | 1.89 safe and non-toxic |

| Packing | Available in 15 Kgs sacks or in larger packings on request |

| Shelf life | eight months |

Concrete Admixture for Durability Hyper 2000

Rice Husk Ash is manufactured by Dr. R.N. Krishna Ph.D., (Civil Engineer) a specialist in the field of admixtures and concrete technology. Hyper 2000™ Rice Husk Ash contains a special blend of siliceous aggregates & abrasion resistant material and inert fillers and when added to cement greatly improves the durability properties of mortar or concrete. The resultant mix with Hyper 2000™ exhibits the following properties

Applications:

Used in:

Specifications:

| Specific gravity | 1.89 safe and non-toxic |

| Packing | Available in 15 Kgs sacks or in larger packings on request |

| Shelf life | eight months |